The adjustable wrench offers versatility and convenience compared to standard wrenches that have a fixed size. You’ll find a wide variety of adjustable wrenches that are designed to meet certain needs.

While the adjustable wrench does have a few issues compared to standard fixed wrenches, their versatility makes them a must-have for most professions and around the home.

What follows are seven of the most common types of adjustable wrenches. Each one has its particular use and remember that they come in different sizes to meet different needs.

1. Crescent Wrench (Open-End Adjustable Wrench)

Arguably the most common and versatile of all adjustable wrenches is the crescent wrench. Sometimes called an open-end adjustable wrench, the crescent wrench is designed to fit nuts and bolts of widely ranging sizes.

Design:

The crescent wrench has a fixed jaw on one side and an opposing jaw that can be adjusted using a thumbwheel worm screw. This allows you to change the size of the opening with your thumb on the hand that is holding the crescent wrench. This makes it quite adaptable and easy to use in most situations.

The jaws are also angled so that you can apply more force to turning the wrench after connecting it to the nut or bolt.

The head of the wrench is often angled in relation to the handle, which allows for greater leverage when turning and more convenience in tight spaces.

The crescent wrench is available in many different sizes from four inches up to four feet, although the latter are only used in special situations that would be beyond what most professionals and homeowners would need them to perform.

Uses:

Crescent wrenches are used in a wide variety of professions as well as around the home. You’ll find them most often used in automotive, plumbing, and for DIY and home repair works.

Their versatility is such that they are the perfect wrench for the homeowner to make simple repairs, assemble products, and tighten nuts or bolts on items in their residence.

2. Locking Adjustable Wrench

A locking adjustable wrench is a combination of standard adjustable wrenches with locking pliers. The locking mechanism allows for maximum force to be applied in gripping the object. This allows for better tightening and loosening of typical fasteners.

As with an adjustable wrench, the locking adjustable wrench has a fixed and adjustable jaw.

The purpose of this type of wrench is to lock it into place and improve the overall grip of the wrench itself.

This solves arguably the worst issue with standard adjustable wrenches such as the crescent wrench. Which is the tendency for the wrench to slip and round off nuts or bolts when turning. By locking the wrench in place, it makes for a tighter grip.

Locking Wrench vs Locking Pliers

Beyond the primary difference between wrench and pliers (applying torque vs. gripping), there are two notable differences between a locking wrench and locking pliers.

First, the locking wrench has parallel jaws that are flat or partially serrated. The locking pliers have serrated jaws that are slightly angled for better grip.

Secondly, typically you would adjust the movable jaw on a locking wrench with the thumb-screw located along the handle, whereas the locking plier has its adjustment screw at the rear end of the plier. You can learn more about locking pliers here.

Uses:

The uses of the locking adjustable wrench are widespread from plumbing to construction to standard repairs around the home. Despite their versatility, many people prefer to have separate locking pliers and adjustable wrenches. Perhaps because the locking pliers or vise grips can be used to secure one side while standard wrenches are used to tighten or loosen bolts and nuts.

3. Plumber’s Wrench (Basin Wrench)

The plumber’s wrench may not be quite as common as the crescent wrench, but it may be the most identifiable thanks to its unique design.

Commonly known as a basin wrench, this specialized tool is designed for working with faucet and sink nuts in tight quarters where other types of wrenches can’t reach. It features a long shaft with a jaw at the end—unlike the more commonly used crescent wrench, which is designed for a broader range of tasks.

The movable jaw of the basin wrench is adjusted by turning a T-bar handle, which operates a screw mechanism, allowing the jaw to fit various nut sizes.

Unlike the Crescent adjustable wrench with parallel jaws, the basin wrench’s jaw is typically set at an angle to the handle, which can be pivotal for access in confined spaces. The wrench also has a locking mechanism that secures the jaw’s position for enhanced grip and turning power.

But perhaps the most important difference is that the jaws of the plumber’s wrench are serrated so they can hold onto special types of nuts. As opposed to the smooth jaws found on the crescent wrench.

Applications:

The plumber’s wrench is mostly used for plumbing work, including tightening and loosening certain types of pipes, slip nuts, locknuts, and basket strainer nuts. The most common type of plumber’s wrench has a jaw range of one to three inches.

They do not come in as many wide variety of sizes compared to crescent wrenches, but there are some which are quite large.

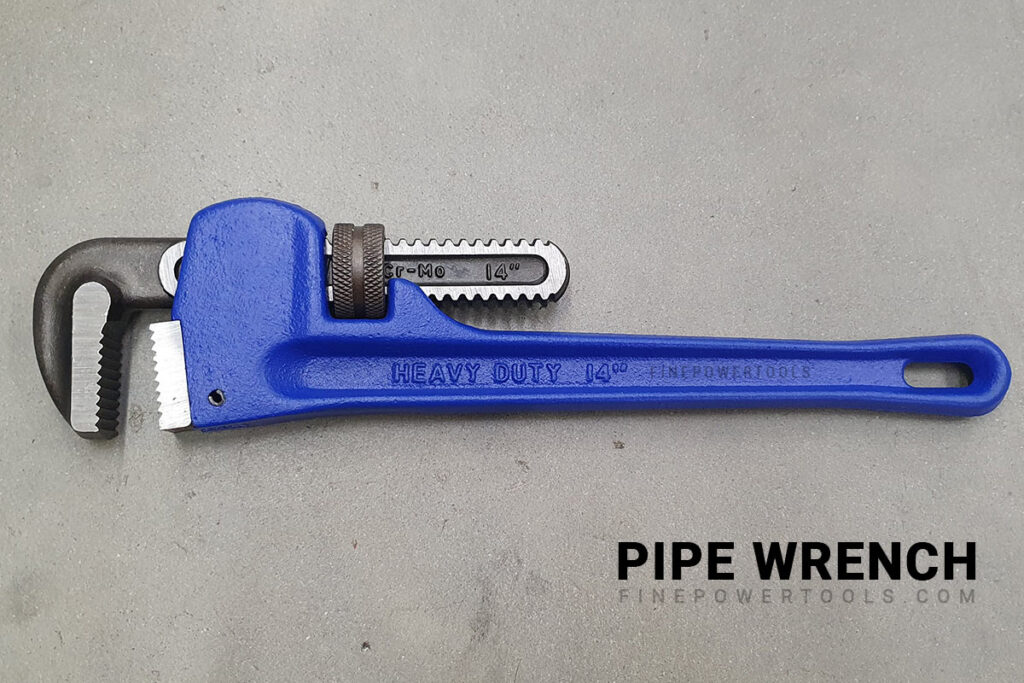

4. Pipe Wrench

A pipe wrench is in many ways like an adjustable wrench. A pipe wrench has the same fixed and adjustable jaw, a screw used for opening or closing the jaws, and the same vertical design with mostly straight jaws as opposed to angled ones.

The main difference is that the pipe wrenches, as the name suggests, are designed to grab onto pipes and not nuts or bolts. You may notice that the serrated jaws, while not fully angled, are slightly slanted so they can grab onto a pipe easier. The teeth on the jaws allow for a tighter, more secure grip on the pipe so that it can be turned easier.

Pipe wrenches come in a wide variety of sizes that range up to two feet long with a jaw opening of five inches wide. Such large pipe wrenches are only used in certain industrial applications. Most pipe wrenches range from eight to twenty-four inches long to handle smaller pipes found within the home.

Uses:

The most common use of pipe wrenches is to adjust, tighten, and loosen pipes. Pipe wrenches are most used in the gas and liquid piping industry. But they can also be found around the home for basic plumbing repairs.

Their design makes them the perfect counterpart for the crescent wrench, allowing the homeowner to repair and replace a wide range of items while only using two types of wrenches.

5. Monkey Wrench

The monkey wrench is a term that many people have heard, but they may not have seen the wrench itself.

During the early days of my career, I thought a monkey wrench and pipe wrench are the same; wrong! There few important differences between the two wrenches, even though they work on similar principle.

The monkey wrench has the same adjustable and fixed jaw as a pipe wrench. However, the jaws are straight and smooth as opposed to serrated and slightly angled of a typical pipe wrench. But the more important difference is that monkey wrenches tend to be smaller and designed to turn smaller nuts and bolts compared to a pipe wrench.

Usages:

The monkey wrench is primarily designed to turn nuts and bolts, not pipes. The most common sizes are from eight to eighteen inches, though some are up to four feet long.

The monkey wrenches were mainly used to grab and loosen tight or even rusted bolts that cannot be easily removed with other adjustable or standard wrenches. They are mostly utilized for automotive work, construction of railways etc.

These days, the open-ended adjustable spanners have mostly replaced the monkey wrenches.

6. Swedish Pipe Wrench

At first glance, the Swedish pipe wrench has a similar appearance to a pair of vise grips. The jaws have that bird-beak appearance with serrated edges. Plus, you use the lower handle’s section up adjustor to fit and lock the wrench in place.

Most pipe wrenches are from 10 to 22 inches long and can handle items that are up to two and half inches in diameter.

Their bird-beak like jaws means that they are not well suited to fit into tight places, but the angled jaws and long handle do provide for more torque to be applied when turning. The plier like design allows you to grip objects once the jaws are in place.

Applications:

You’ll find Swedish pipe wrenches used mostly in the automotive industry. They are well-designed to remove and replace items such as tie rod ends. However, their serrated jaws make them well-suited to be used as a pipe wrench in loosening and tightening pipes, although they are limited in size.

I often use my Swedish pipe wrench to load and unload heavy steel workpieces into the heat-treatment furnace for hardening.

7. Chain Wrench and Strap Wrench

The chain wrench and strap wrench are similar in terms of its function.

In terms of its appearance, the chain wrench is quite unique compared to other tools in this list. The wrench consists of a handle with a chain attached to one end.

You wrap the chain around the object you wish to remove and tighten it until the grip is secure. By pushing the handle, you can loosen the object in which the chain is wrapped.

A typical chain wrench is from one to two feet in length. Its chain can wrap around objects of various sizes. Because the chain is composed of hardened metal, it can damage the surface of a delicate object.

Chain wrenches are generally designed to remove irregular shaped objects in which their appearance is of no concern. If you are worried about the chain marring the work surface, use a strap wrench.

Both strap and chain wrenches are not often found around the home. They are usually found in construction, automotive, and plumbing industries. The chain and strap wrenches is well-suited to wrap around irregular shaped workpieces and pipes thanks to flexible design.