Reflow soldering is a technology widely used in the electronic industry to join surface-mount components to PCBs. It’s especially effective for soldering small and delicate components that require high precision.

In this article, I will introduce you to this amazing soldering technique; let’s get started!

What is Reflow Soldering?

Reflow soldering is a PCB assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. The PCB design and components’ layout are crucial in reflow soldering to ensure efficient heating of solder and even heat distribution.

Process:

Before soldering, soldering paste with flux is applied on the PCB’s contact pads, and the components are mounted in place, either manually or automatically, depending on the reflowing machine’s type.

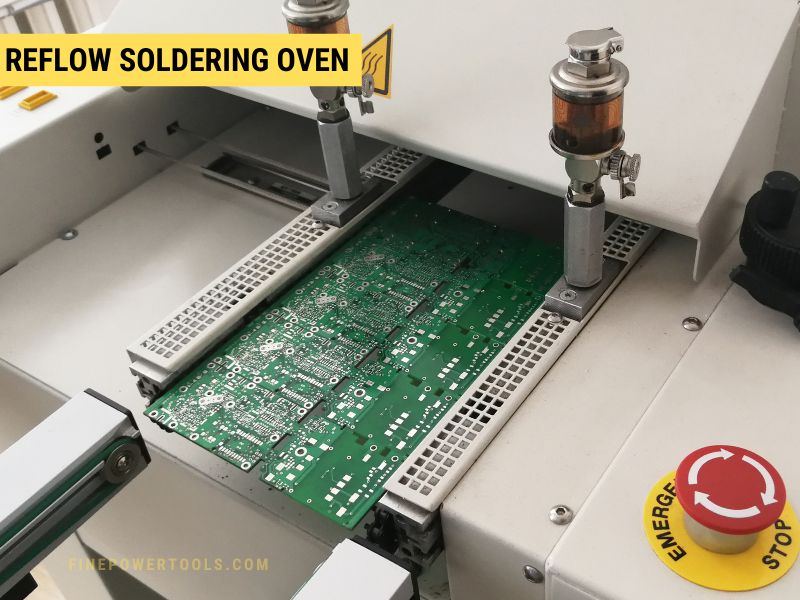

Next, the PCB enters the reflowing oven, which uses an infrared lamp to produce heat and melts the soldering paste, creating mechanical and electrical connections.

All the components are soldered simultaneously, and some machines can solder multiple boards simultaneously, adding speed to the process.

Hot air recirculates through the oven, resembling kitchen infrared ovens, instead of being directly applied over the components. This ensures efficient heat distribution and is more effective than heating the board directly.

Types of Reflowing Soldering Machines

Reflowing soldering machines can be divided into two main categories:

- Desktop and

- Industrial

If you are an electronics enthusiast or run a start-up and want to speed up your soldering process and reach more professional-looking results than manual soldering, there are some interesting reflowing ovens for under $1,000.

On the other hand, industrial reflow machines are designed for mass production and can effectively solder a wider variety of components.

Let’s take a closer look.

Desktop Reflow Machines or Ovens

These compact machines are designed for small-scale applications like hobbies, prototyping, and small-scale production. Their capacity depends on the machine and the board’s size.

Some models have a drawer-like cartridge where the boards are loaded, while others have openings on the top and a door that securely latches to prevent heat from escaping the machine.

These machines’ most common components are:

- Reflow Chamber: This is the oven’s central part; it houses the heating element/s and the PCBs’ support while being soldered. The internal part of the reflow chamber is designed to enhance airflow during the soldering process.

- Heating Element: Desktop reflow machines feature one or two infrared lamps or arrays of strategically distributed ceramic heaters. Due to these machines’ simplicity, the heating element is also in charge of the pre-heating stage.

- Cooling System: These machines have coolers to prevent their circuitry and components from overheating. Some models also feature a basic cooling system to gradually cool down the PCBs after soldering, preventing thermal stress.

- Controller and User Interface: Reflow ovens include controllers to allow operators to regulate the temperature and choose among different temperature profiles, heating times, and other parameters. Depending on the model, they may include advanced features like touchscreen control panels, real-time temperature readings, etc.

- Power Supply: These devices come in different wattages and rely on a power supply to operate the heating element/s and the controller.

Industrial Reflow Machines

These machines come in different sizes, models, and configurations. The most advanced and expensive models include robotized solder paste and assembly. Industrial reflow machines offer more accurate temperature regulation, different temperature zones, and advanced conveyor systems, and they can solder several boards per minute with little or no operator intervention.

- Conveyor System: The conveyor system is in charge of transporting the circuit boards through the different stages of the reflow soldering machine. Some models allow program direction changes depending on the assembling requirements and components used.

- Pre-Heating Zone: Unlike desktop reflow ovens, industrial reflow soldering machines feature a specific preheating zone. Preheating reduces the risk of thermal shock and soldering defects, activates the solder paste’s flux, and prepares the board for the soldering process.

- Reflow Chamber or Soldering Zone: This is the main part of the machine. Industrial reflow machines use a combination of infrared heaters and convection systems for enhanced airflow.

Some advanced machines have multiple heating zones with independent temperature settings to allow soldering large boards with sensitive components or different temperature needs. Convection is achieved by the chamber’s designs and the help of fans or blowers that circulate the hot air to ensure even heat distribution. - Heating Elements: Most industrial reflow soldering machines use infrared lamps, heating panels, or a combination of both. They generate the heat to melt the solder paste and create the solder joints.

- Cooling Section: After the soldering area, an array of fans cools the PCB and the components down to help the solder paste dry, prevent damage due to excessive heat, and prevent thermal shocks.

- Fume Extraction System: Reflow soldering machines feature fume extraction systems to extract and filter the fumes produced during the soldering process, ensuring a safe working environment.

- Control Panel: Industrial reflow soldering machines can have complex control panels to regulate the process parameters, such as temperature profile settings, conveyor and fan speed, and other settings to achieve excellent results. Some control panels are complex, requiring a deep understanding of the components involved, board design, solder paste, and how the machine works.

Industrial reflow soldering machines can solder almost all SMT component types at an incredibly high speed. However, they are much more complex than their desktop counterparts and require more planning and engineering for effective results.

How it Works

Desktop reflowing ovens involve more manual work than industrial ones; however, the processes are similar.

- Solder Paste Application: The first step consists of applying solder paste with flux over the PCB’s soldering pads of the components to be soldered. It’s very similar to manual solder SMDs using a manual reworking station. For complex circuits, pin patterns, and/or speeding up the process, it’s practical to use a stencil, reducing the margin for mistakes.

- Component Placement: Then, it’s time to place the components over the soldering paste. It’s important to ensure they are in the correct position and that the pins are properly placed over the PCB’s contact pads.

- Heat Application: It’s important to understand the three steps of heating involved in reflow soldering:

- Pre-Heating: This first step consists of heating the board and the components to avoid thermal shocks caused by sudden temperature changes. Some machines have a pre-heating station, while others do it automatically in the heating chamber.

- Thermal Soak: This second stage ensures a steady and even temperature across the board and starts melting the solder paste to begin the soldering process. Setting the temperature of this stage is key to prevent soldering defects like fading.

- Reflow: Reflow happens when the heaters have reached their maximum temperature. The solder paste melts completely, creating effective solder joints.

- Cooling: Once the components are soldered, the PCB is slowly cooled to avoid thermal shocks and prevent soldering defects and board deformation.

Pros and Cons of Reflow Soldering

Making a list of reflow soldering pros and cons would be pretty unfair because there are components that couldn’t be soldered without this technology and, even when some hard-to-solder components could be manually soldered using a reworking station, it would be impossible to run mass production batches of circuits featuring those components without this method.

In terms of pros and cons, a fairer but more difficult comparison would be comparing different models of reflow soldering stations.

In my experience, a reflow oven or a more expensive machine is more a question of timing and evaluating the cost and effort involved. When working on complex SMT projects, you already have to deal with complicated patterns and stencils for efficient solder paste application, so a decent desktop reflow oven can be an excellent addition to your soldering arsenal if you frequently deal with surface mount boards and components.

However, reflow soldering doesn’t have the advantage of correcting soldering defects on the fly, so you will have to design your boards and know your soldering paste very well to avoid frustration.

Another thing to consider is that the most affordable models are only compatible with some components. If you use mixed SMD and through-hole soldering, you would have to manually solder the through-hole components because of the lack of equally affordable wave soldering machines.

Is it Worth?

Reflow soldering machines are a dream for most electronic enthusiasts; the big question is if you really need one.

If you are running a start-up, it is more a question of when and choosing the machine’s specs wisely and considering the costs associated with training and engineering related to the use of the machine and compatible circuit design.

Wave Soldering vs Reflow Soldering

Wave soldering and reflow soldering are complementary soldering techniques.

In the chart below, you will find their main differences:

| Wave Soldering | Reflow Soldering |

| Ideal for through-hole components but can be used with some SMD components. | Suitable for SMD components only. |

| The machine applies solder. | Solder must be applied before entering the workpieces into the machine. |

| Wave soldering machines are often more complex. | Most models are simpler and have fewer moving parts. |

| It’s faster and more cost-effective than reflow soldering. | It’s less cost-effective and can be much slower than wave soldering. |

| It can solder large components that require solder with a high melting point. Ideal for power electronics. | It’s not suitable for large components, and it’s not meant for power electronics. |

| Requires more supervision and monitoring while soldering than reflow soldering. | It doesn’t require much supervision. |

| Few or no low-cost machines are available. | Many entry-level and hobbyist products are available. |

Common Applications

- SMD Components: Reflow soldering is perfect for soldering SMD and SMC components onto PCBs.

- Mass Production: Reflow soldering is ideal for high-volume production lines, simultaneously enabling rapid and accurate soldering of multiple boards.

- Prototyping: Reflow soldering machines are great for prototype assembly and testing of SMT circuits.

- Electronics Assembly: Reflow soldering is widely used to assemble many high-end electronic devices, such as motherboards, control boards, and devices using SMD components. They are necessary for circuits that use components like BGA, which have connectors that can’t be soldered using soldering irons or wave soldering.