Are you looking for a versatile, effective tool to flesh out your garage or workshop? If so, then you might want to consider a miter saw.

A Miter saw (or mitre saw) is a handy power tool for cutting, trimming, or framing.

Any handyman, power tool enthusiast, or professional carpenter will find that a good miter saw makes their work easier, faster, and better. But, they can also be pretty expensive (as most specialty tools are), so before you rush out to buy a miter saw, you might want to learn as much as you can about miter saws and what to look for when buying one.

To help potential miter saw owners out, I have written this complete guide, which will tell you everything you need to know about Miter-saws.

Miter Saw Uses

A miter saw is used to make precision cross cuts, angular cuts (miter), bevel cuts and compound angle cuts on wood, plastic, and soft metals. I will explain each of these cuts in the next section.

- Trim Work: Miter saws are commonly used for cutting decorative trim due to their ability to make precise angled cuts. You need a this saw when when installing baseboards, shoe molding, crown molding, casing, etc., especially when you want to cut large amount of trim pieces.

- Framing: If you are constructing a house, you will find that carpenters often use miter saws for cutting framing materials such as studs, joists, and rafters to size.

- Craft Work: It is a very useful tool for cutting photo frames, making decorative boxes such as jewelry boxes or storage boxes, building wooden models, crafting wooden signs with beveled edges, etc.

Cut Terminology (Types of Cuts)

Before getting into the different types of miter saws and what to look for, you should be familiar with the different types of cuts that miter saws can make.

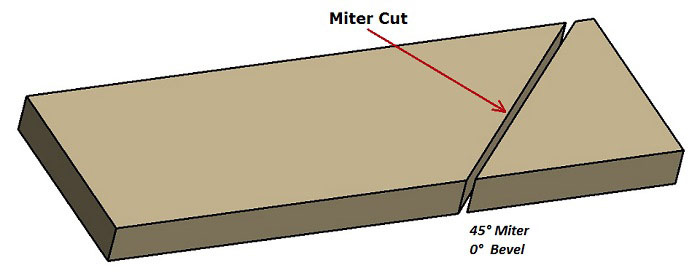

1. Miter Cut

This is a cut to the length of a piece, where the blade is set at any angle besides 90 degrees. You can either make left or right miter cuts. Miter cuts are usually used to make miter joins (common in pipes, picture frames, etc.).

2. Bevel Cut

A bevel cut can only be made by compound miter saws (I’ll cover the different types of miter saws in the next section). Bevel cuts are cuts to the width of a piece, which are made at an angle less than 90 degrees. They are often done to modify the edge of a piece (either for safety purposes or to make it look better); these cuts are also done to make two pieces fit together.

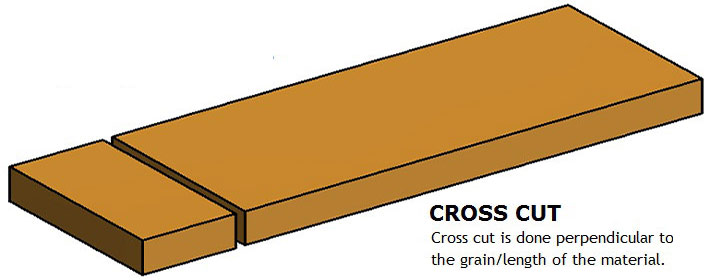

3. Cross Cut

Crosscuts are your basic 90-degree cuts that go along the width and length of a piece. These cuts are popular for framing boards or for doing decks.

4. Compound Cut

Compound cuts are essentially a mixture of bevel and miter cuts. They are cuts at angles other than 90 degrees, made to both the length and width of a piece. Obviously, you will need a compound miter saw to perform this type of cuts.

Now that you know the uses of this nifty saw, let me help you to choose the best miter saw.

Types of Miter Saws

There are mainly three types miter saws: Basic, Compound and Sliding Compound.

1. Basic Miter Saw

These are your standard miter saws. They can make miter cuts and cross cuts easily, but they lack a bevel, and so cannot make bevel cuts. They are great for making frames, molding, doing finishes on carpentry jobs, and other jobs that require simple cuts.

These types of miter saws are generally lightweight and less expensive than other types of miter saws. That makes basic miter saws a good option for beginners.

Pros

- Affordable price

- Can do miter and cross-cuts

- Lightweight, robust and durable.

- Easy to operate

Cons

- No bevel option

- Can not cut compound angles

2. Compound Miter Saw

Compound miter saws are able to make straight cuts, cross-cuts, miter cuts, and bevel cuts; so they are “do it all” type of miter saw. They are heavier and a more expensive because of this.

It is also worth noting that there are two types of compound miter saw,

- single bevel and,

- dual bevel.

So, what’s the difference?

Single Bevel

Single bevel compound miter saw can perform any angular cuts; but will make a bevel cut only in a single direction, either right or left. So, if you want to make a cut in the opposite direction, you need to flip your workpiece or in case your workpiece to large, move the entire miter saw.

Double Bevel

A dual bevel saw will allow you to make bevel cuts in both directions, so that you do not have to flip your work. This highly convenient when you have to make a lot of bevel cuts in both directions on a single workpiece.

For a more detailed explanation, see single vs. double bevel miter saw comparison guide.

Pros & Cons of Compound Miter Saw

Pros

- Versatile power tool

- It can make cross-cuts, miter cuts, bevel cuts and compound cuts (miter + bevel)

- Excellent choice for most people.

Cons

- Expensive when compared to basic

- More complex in operation.

3. Sliding Compound Miter Saw

As you can probably tell from the name, these types of miter saws are very similar to compound saws. The main difference being the addition of a sliding arm; which allows you to cut wider pieces.

They are a bit heavier and more expensive than regular compound miter saws; but if you do a lot of cutting of wider stocks, the sliding arm is worth it.

You can find all about sliding compound miter saw here.

Pros

- Most advanced option.

- Can cut any angle

- Useful for professional woodworkers who frequently cut wider workpieces

Cons

- Most expensive type.

- They are larger and heavier.

- Not suitable for novice users.

Buying Guide

What to look for while buying a miter saw?

Here are some of the most important features you must consider while picking new saw:

Power

You want your miter saw to be powerful, so when shopping for a miter saw, keep an eye on its amp levels. 10-15 amps of power is the usual range you will see when shopping for a miter saw.

I recommend going for a higher amp level, 15 amps of power is ideal.

You will also want to keep in mind what type of motor the miter saw is using. Belt drive motors tend to burn out quicker than direct driver motors, so try to avoid belt driven motors.

Size

Depending upon the diameter of the blade, different size saws are available. The most commonly available are 10 inches and 12 inches miter saws.

While a 10 inches miter saw is enough for most users, the bigger diameter blade can cut wider and deeper.

Keep in mind that you can not install a 12 inches blade on a 10 inches saw.

Blade Type

There are generally three types of blades that come with miter saws.

The first type is regular old steel blades; these work well enough for wood, but they will dull quickly if you use them on tougher materials like hardwood or metal.

The second type is called “high speed” steel (HSS) blades. These are generally the same as regular steel blades, but are slightly tougher. HSS saw blades can retain the cutting edges at a much higher temperature resulting in longer tool life.

Finally, the best type of blade is carbide tipped blade; these blades last longer and can easily cut through the toughest material without dulling. Obviously, if you are buying a miter saw, then you want saw blades that won’t dull; so I recommend that you look for carbide tipped blades if possible.

Laser Guiding System

It is not essential to have a laser guidance system on your miter saw, but it can be very helpful. I find that I make more accurate cuts when using a laser guide; this is true for many others as well.

If you are buying a miter saw for a beginner (or you yourself are a beginner) then a laser guidance system will be very helpful to them when they first start using the miter saw.

Corded vs Cordless Miter Saw

Cordless miter saws are an ideal choice for those who are looking for portability. If you have to carry your miter saw to different locations, a cordless miter saw is a very convenient option.

But for most of you DIY enthusiasts out there, I would suggest you buy a corded saw since they are less expensive and more robust.

Dust Blower

When you are working on a project, sawdust builds up very quickly. So, when looking for a miter saw, look for one that has some sort of system in place to blow dust away from your workstation. Some high-end ones even have a system where you can hook up a vacuum cleaner to the machine and have the dust directly sucked into a bag.

Sure, you can use a can of compressed air to blow the sawdust away, but that requires you to take your hands off the machine, which can be annoying.

Safety Features

Keep an eye out for important safety features when looking for a miter saw.

Blade Guard

The blade guard is the most critical safety feature of any circular saw. In case of a miter saw blade guard covers the outside of blade when the arm is in up position and moves inside when you drop the saw to cut.

If you are using it for the first time, you may find it hindering your view of the cutting area. Personally, I don’t find it to be a big issue since I am used to it. However, I have heard many people complaining about the guard. I strongly recommend you to use blade guards to protect yourself from accidents.

Tip: Buy a miter saw with a transparent blade guard that will provide you with a clear view of the cut.

Electric Brakes

Miter Saws with electric brake can swiftly slow down the rotation of the saw blade. The blade has to rotate at very high speed, generally above 3000RPM to make smooth cuts. The electric brake is a safety feature that will allow the blade to stopped quickly when you release the power button and raise the saw arm after making the cut; thus reducing the likelihoods of injury.

On the other hand, without the electric brake, the blade will keep rotating due to the momentum and will take considerably longer period of time before the blade comes to a halt.

Clamps

With a miter saw you are making the cut by using the blade that rotates at very high RPM is dropped on to the workpiece that is held against the fence. While experienced users frequently perform the cutting handheld, you never know when things can go wrong.

A loosely held workpieces can get slipped during cutting and it can be flung around and hit your body causing damages.

Use safety clamps or vice to firmly secure the workpiece before you switch on the blade. This will not only keep you safe but will also improve the quality of the cut.

These tools are incredibly dangerous, so electric brakes and extra guards can go a long way to making miter saws much safer to use.

Miter Saw F.A.Q

Following are some of the most frequently asked questions by new users who are shopping for a miter saw.

What Can You Do With a Miter Saw?

A miter saw can be used to cut straight and angular cuts across the surface and on the face of the work-piece. To be more precise, you can use a miter saw to do crosscuts, miter or angular cuts, bevel cuts and a combination of crosscut and bevel or miter and bevel cuts.

If you are interested to learn more, see the tips on how to use miter saw.

What Is the Difference Between a Chop Saw and a Miter Saw?

You might have heard people often using these two terms interchangeably. However, they are different machine tools.

The primary difference between a miter saw and chop saw is that a chop saw can only be used for crosscuts, i.e., straight cuts perpendicular to the length of the workpiece. On the other hand, a miter saw can cut 90-degree crosscut, cut along an angle and produce bevel cuts.

There are few other differences.

- Chop saws are heavy duty machines that cut tough materials like metals.

- Generally, abrasive parting-off wheels are used as cutting blade.

Do I Need a Miter Saw, if I Already Own a Circular Saw?

Circular saw is very versatile tool that can perform most type of straight cuts, but it is less accurate. A miter saw on the other hand is precision machine designed specifically for angular cutting.

For more details please refer to circular saw vs miter saw page.

What Is Double Bevel Miter Saw?

A double bevel compound miter saw can produce bevel cuts in both left and right direction in the same settings of the workpiece. That means you don’t have to move and flip your work to make a bevel cut in the other direction.

10 Inch vs. 12 Inch, Which Miter Saw Is Right for Me?

These are the two most popular sizes available in the market. A 12-inch miter saw can cut wider and deeper than a 10 inch saw due to the bigger diameter blade.

If the size of your workpiece is bigger than 2 x 6 inches, then get a 12-inch saw.

Anything smaller, you can cut on a 10-inch miter saw.

How Much Can a 10-Inch Miter Saw Cut?

The size of the stock you can cut depends upon the angle of cut. The typical 10-inch miter saw will cut the following size.

- Crosscut at 90-degree angle: Up to 5.5 inches wide. or 2 x 6 lumber.

- Miter cut at 45-degree angle: 2 x 4 lumber

- Plywood: 10 miter saw can cut thickness until 1.25 inches deep.

12 Inch Saw cutting size

A 12 inch miter saw will cut as wide as 7.5 inches up to to a thickness of 3.5 inches. That means you can easily cut a 2 x 6 lumber at 45 degrees and cut a 2 x 8 lumber at 90-degree crosscut.

Can You Use a Miter Saw to Cut Metal?

The short answer is yes.

The longer answer is, it depends on the cutting blade and the hardness of the material to be cut. A high-speed steel (HSS) blade can cut softer metals like Aluminum, whereas ferrous metals will require carbide blades for efficient cutting.

Personally I recommend you to get a carbide tip miter blade to do all your metal cutting work. They last longer and cut better.

Closing Thoughts:

The above miter saw buying guidelines and answers to the common questions should give you a good idea on the important factors to look for when selecting the most suitable miter guide for your work.

Follow the safety rules and good luck with your next project.

Back to Contents

- Miter Saw Uses

- Cut Terminology (Types of Cuts)

- Types of Miter Saws

- Buying Guide

- Miter Saw F.A.Q

- What Can You Do With a Miter Saw?

- What Is the Difference Between a Chop Saw and a Miter Saw?

- Do I Need a Miter Saw, if I Already Own a Circular Saw?

- What Is Double Bevel Miter Saw?

- 10 Inch vs. 12 Inch, Which Miter Saw Is Right for Me?

- How Much Can a 10-Inch Miter Saw Cut?

- Can You Use a Miter Saw to Cut Metal?

- Closing Thoughts: